Retrofit your machine with Eurosoft support

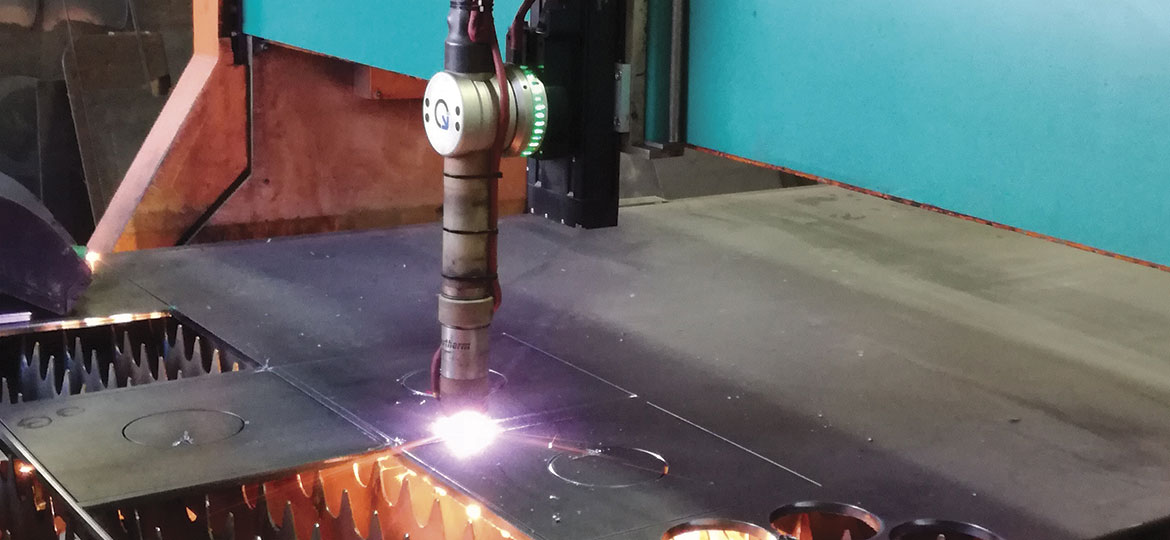

The purchase of a new metal sheet cutting machine hugely impacts the company's bottom line.

Moreover, the optimum life cycle of the machine is only 8-10 years.

This unusual feature for a machine tool is primarily due to the type of cutting technology, environmental conditions and other minor factors.

Until recently, it was common practice to replace defunct machines with a new, more reliable one.

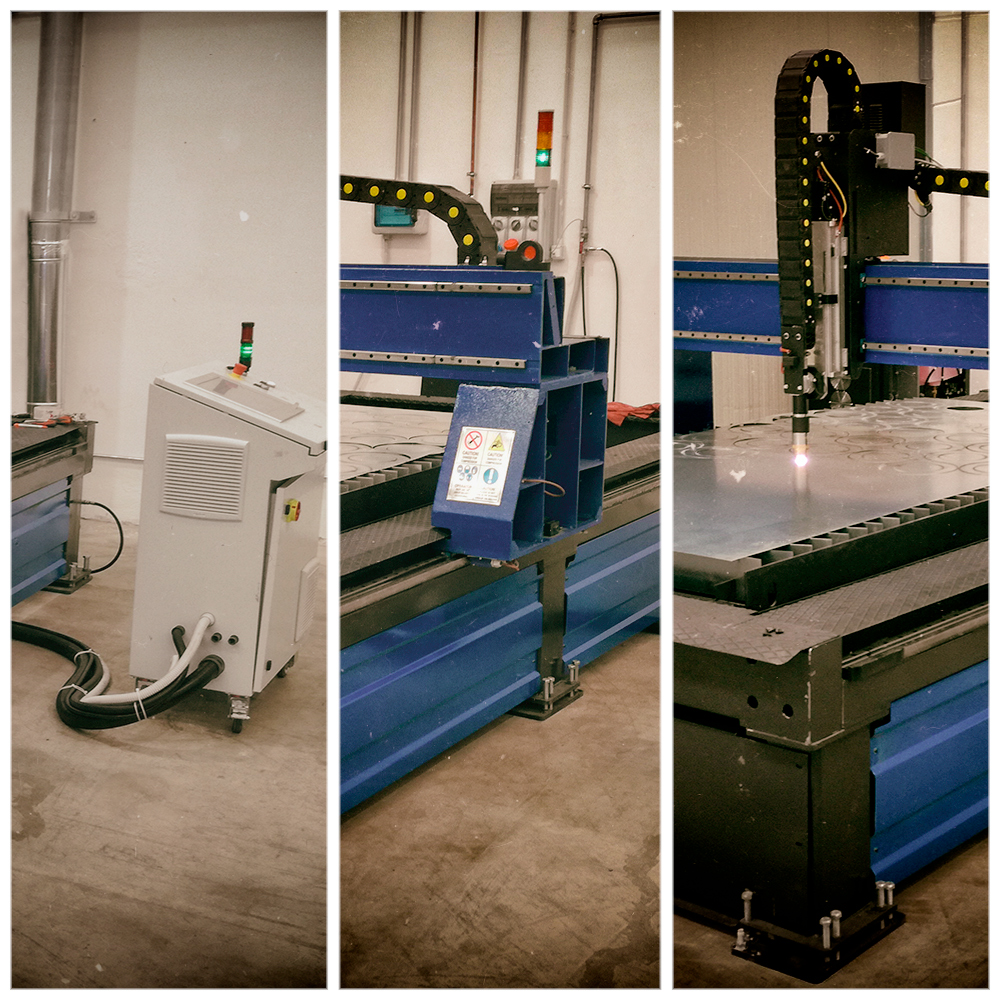

Today, regards many new machines especially mid-range ones, mechanical technology has not evolved sufficiently to make a difference when compared to old machines. Therefore, a solution that is increasingly becoming a field with a clearly defined cost/benefit ratio, RETROFIT, is absolutely advantageous for companies.

This operation is not to be considered a fall-back, or a second-hand solution but rather an intelligent choice that permits the update of an already-installed machine without the need to carry out further work to adapt electrical and suction systems, nor the reorganization of the production areas.

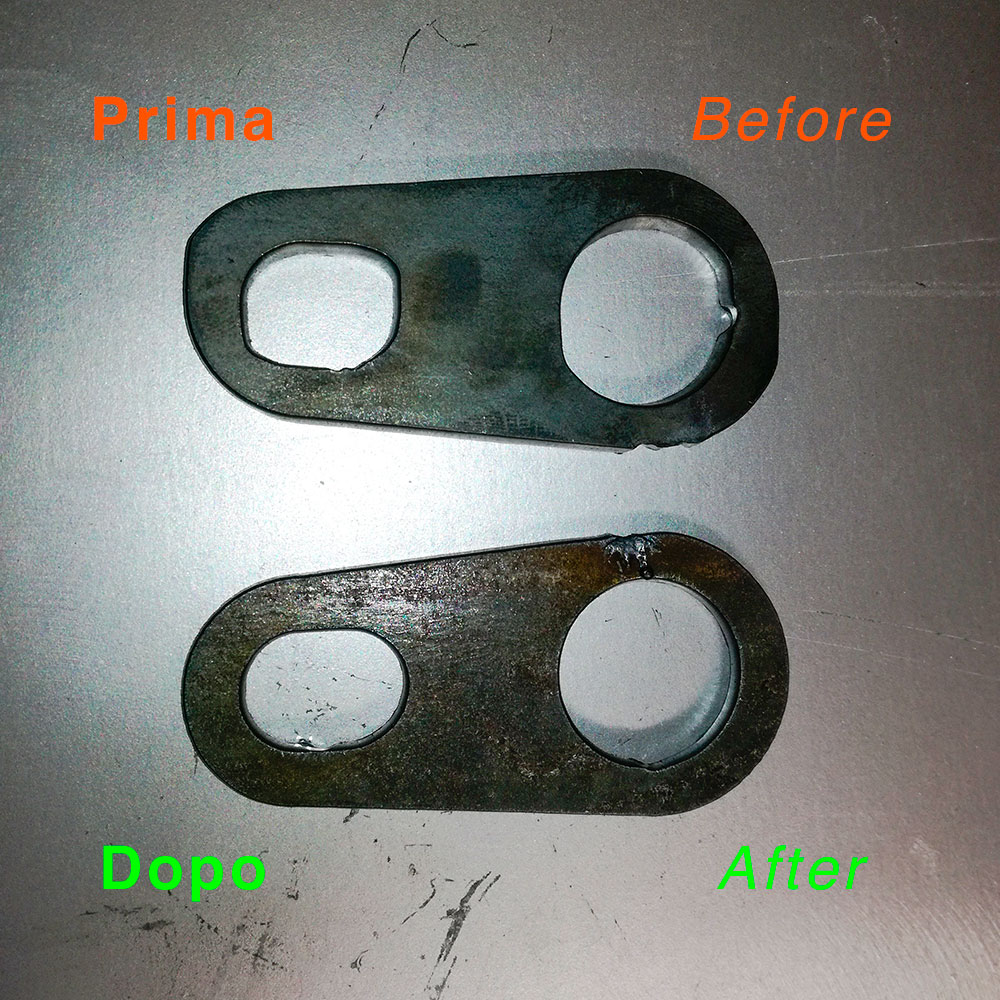

Retrofit operations, in almost all cases, make it possible to return the cutting machine back to 'improved' conditions compared to its brand new state, saving well over 50% compared to a new one. Eurosoft can deliver a vertical, up-to-date, modular and customizable solution for the complete renewal of your work tools.

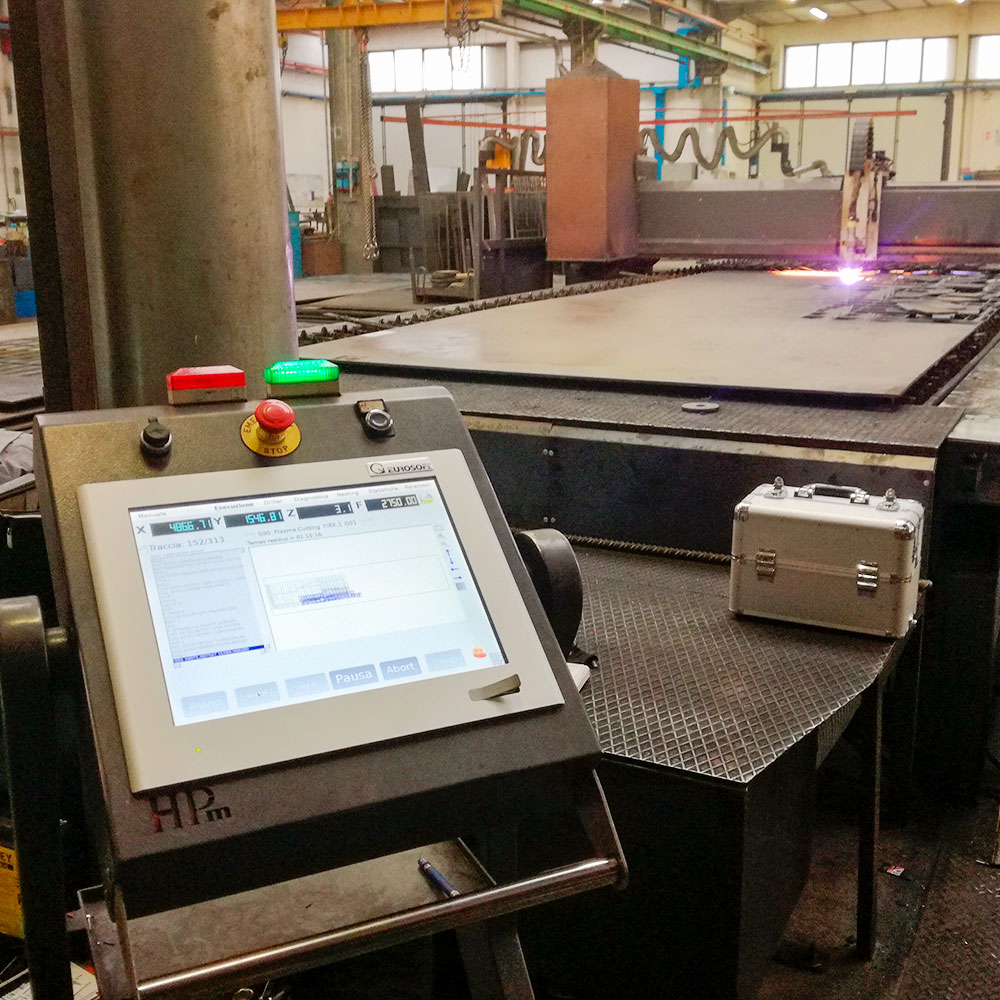

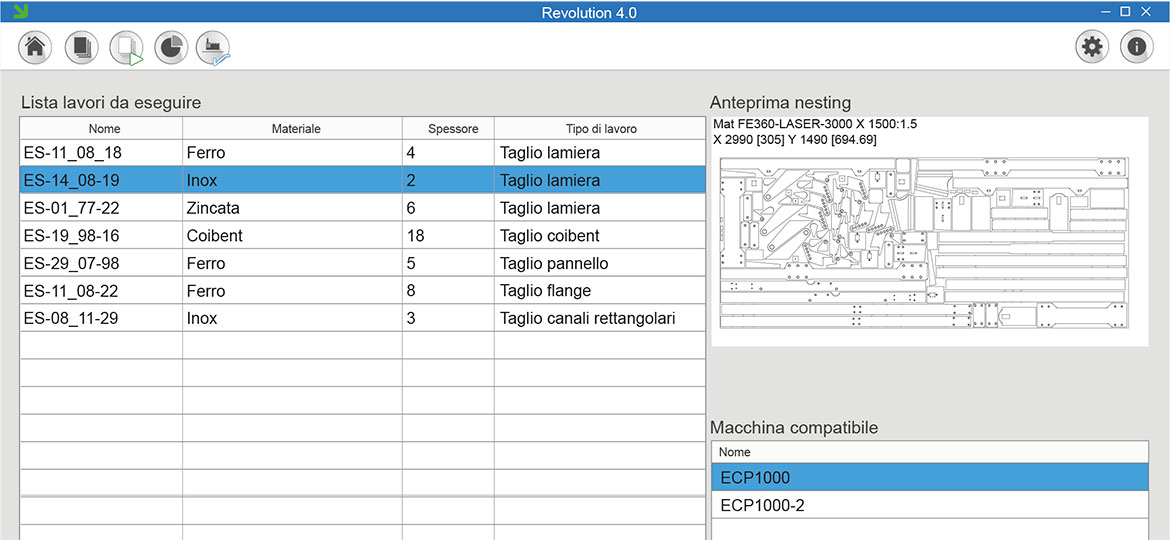

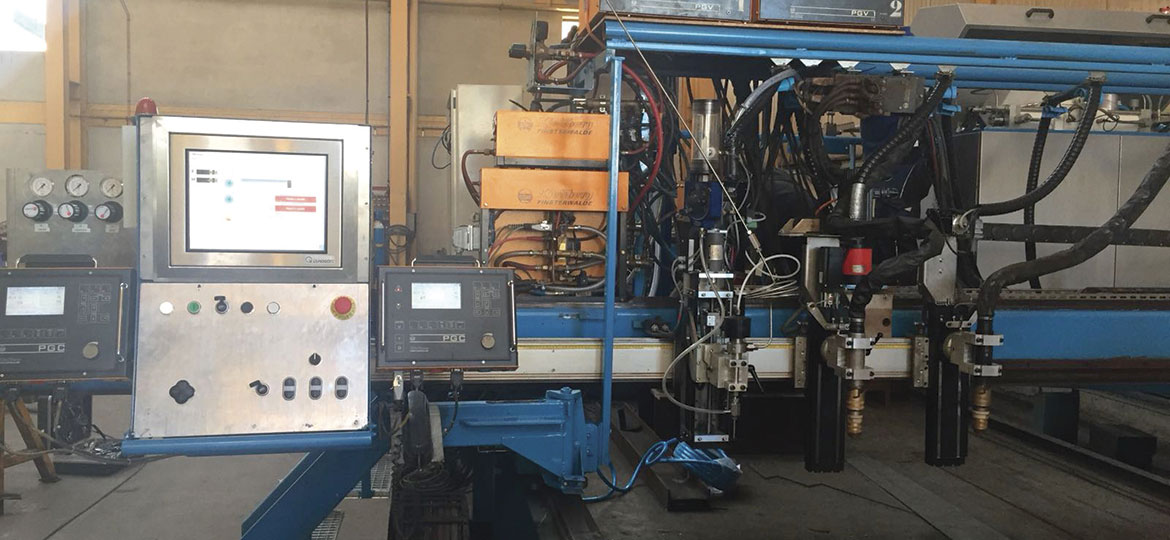

CNC

The heart of the machine

The numerical control ECP1000 for the thermal break represents the most solid solution, simply and effective entirely developed by Eurosoft

The elevated functionalities of the system represent alone a very important value added for your machine. This component is used in all the possibles retrofit levels.

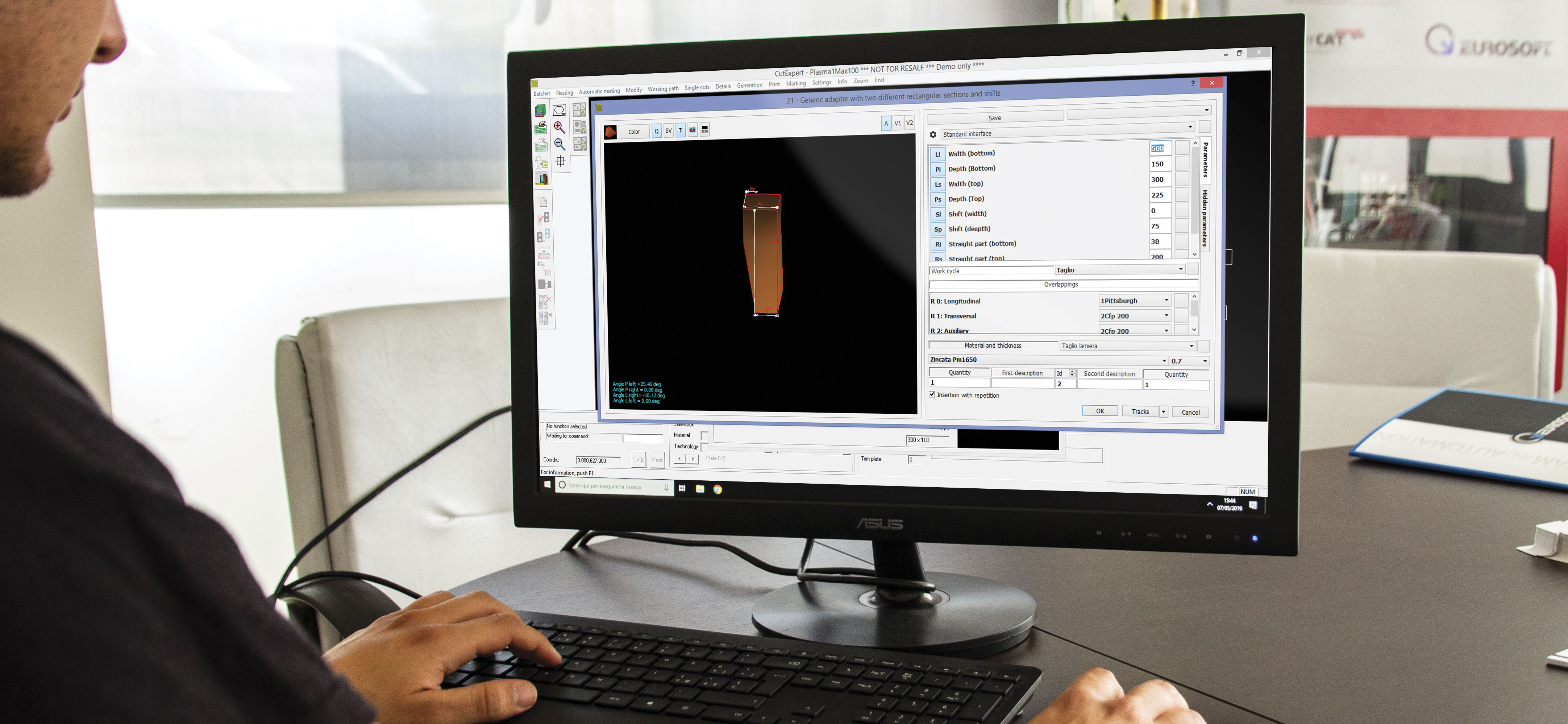

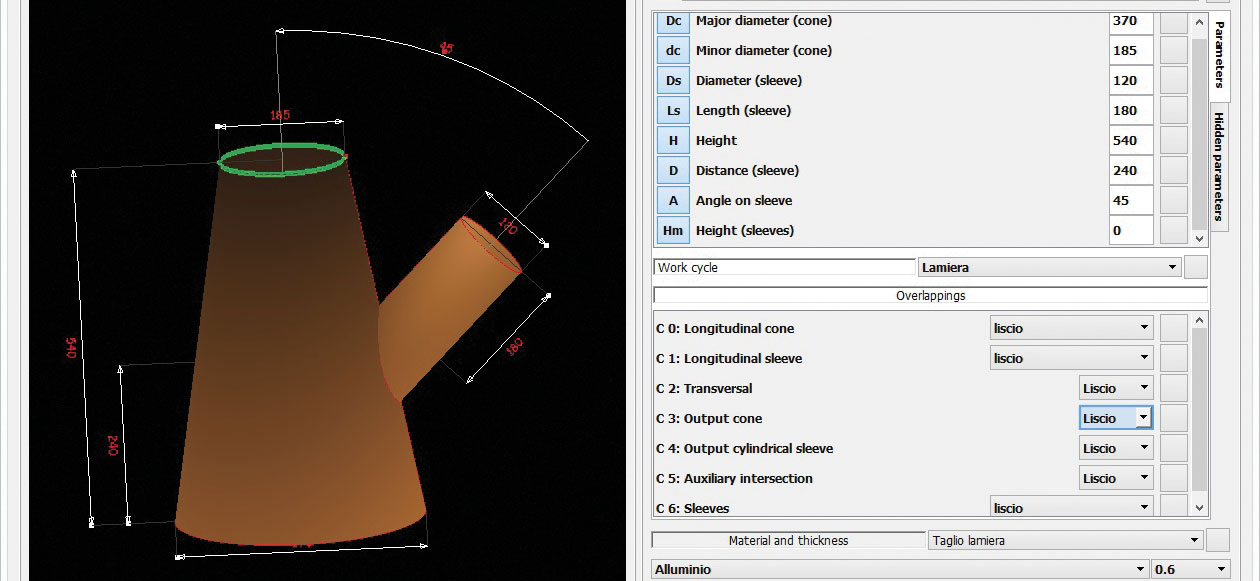

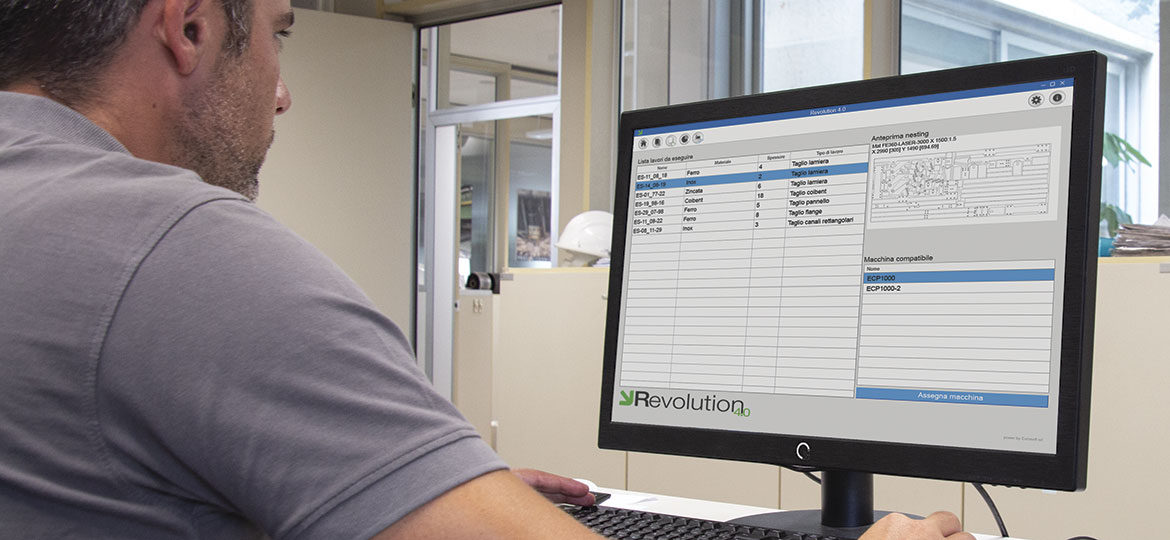

Cad/Cam

We replace your old software with CutExpert, the tried system projected and realized by Eurosoft for the thermal break, that englobes the function of automatic nesting. CutExpert is able to converse with plasma, laser, oxy, waterjet cutting machines or any other machine tool for the bidimensional cutting.

It is a software that adapts perfectly to the HVAC sector providing requirements to cope with the continuous and sophisticated market requirements.

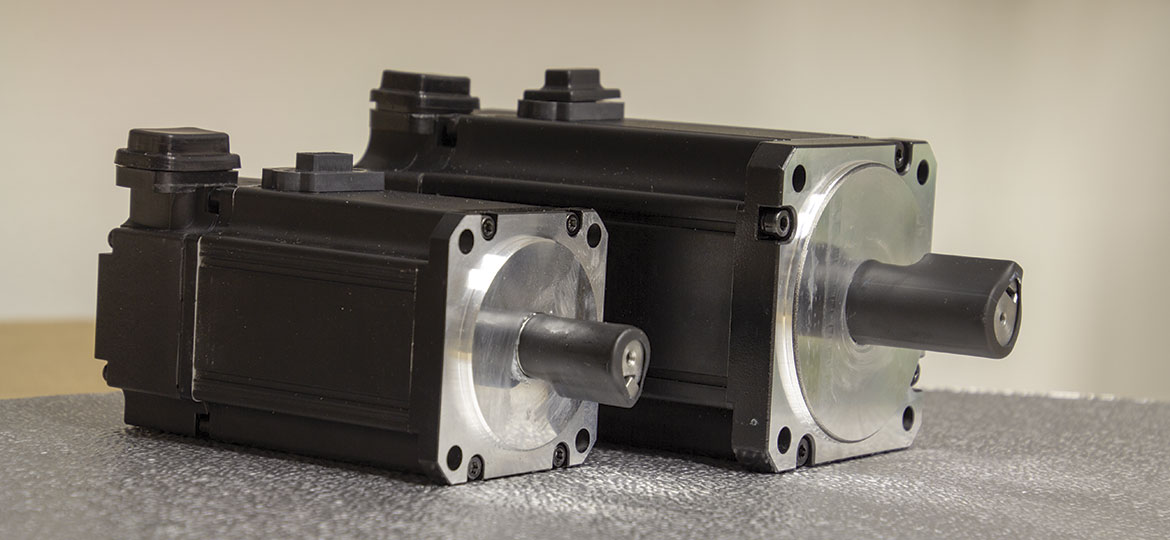

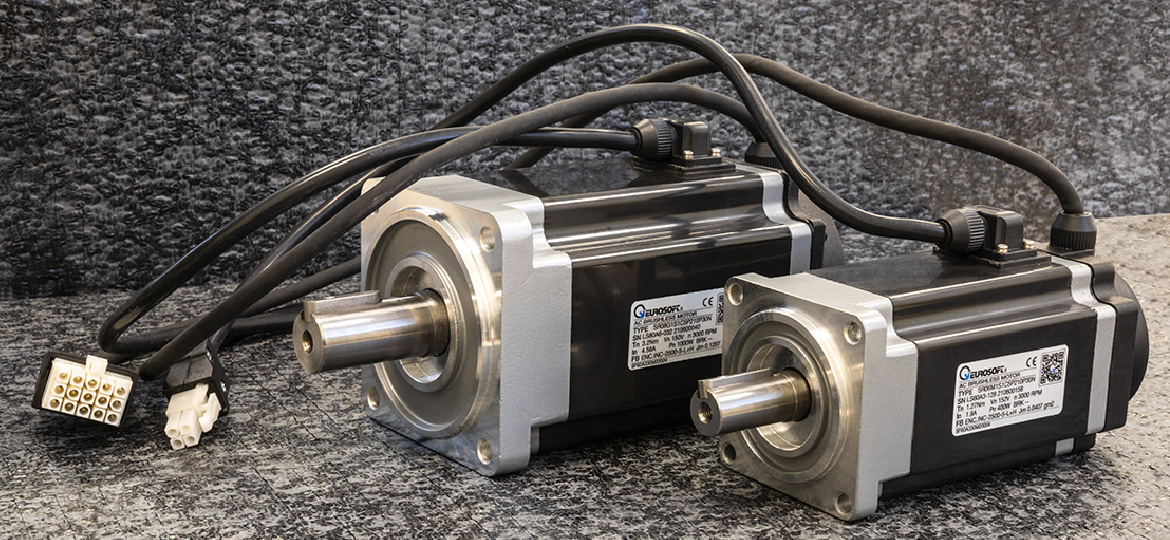

Driver and motor

The replacement of drives and motors is an option to be evaluated. It is possible to replace only the drives, preserving the motors, or to replace both. Being based on Ethercat® the choice of the possible solution is practically infinite. We have in the stock a wide range of solutions, to the cheapest to the best performing.

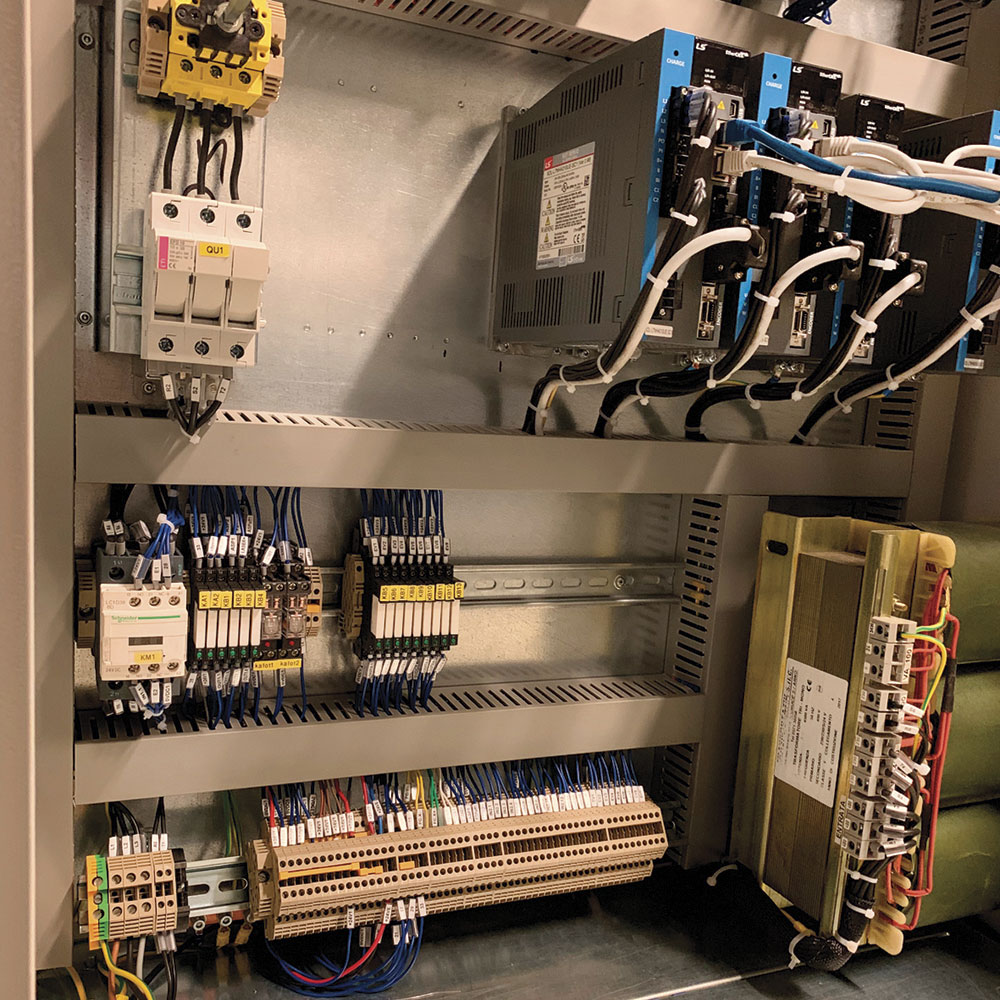

Wiring on the machine

In case of necessity we carry out the supply of the electronic spinning in order to adjust the security of the machine to current regulations.

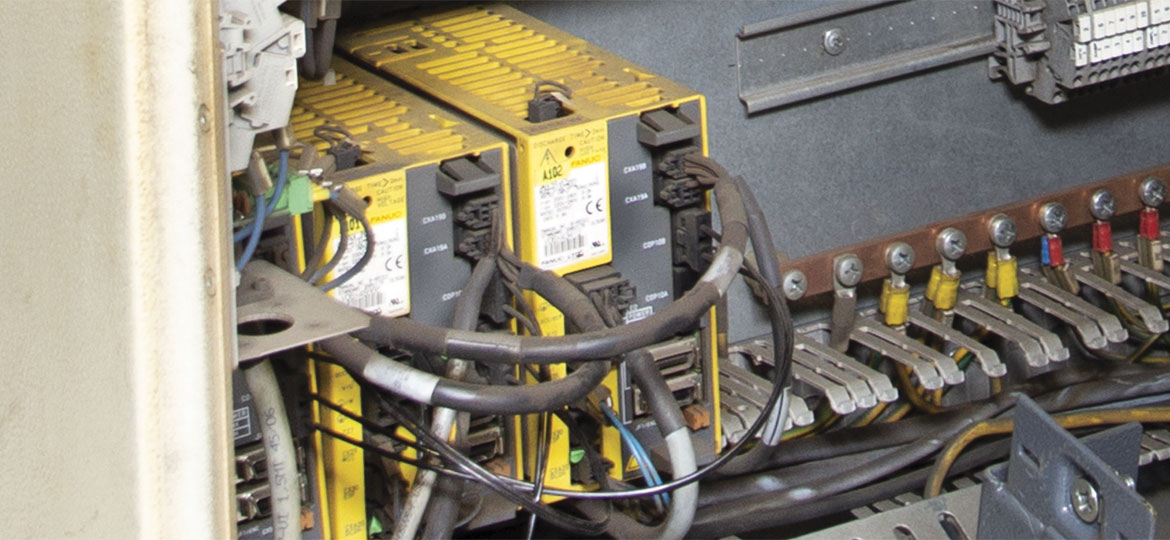

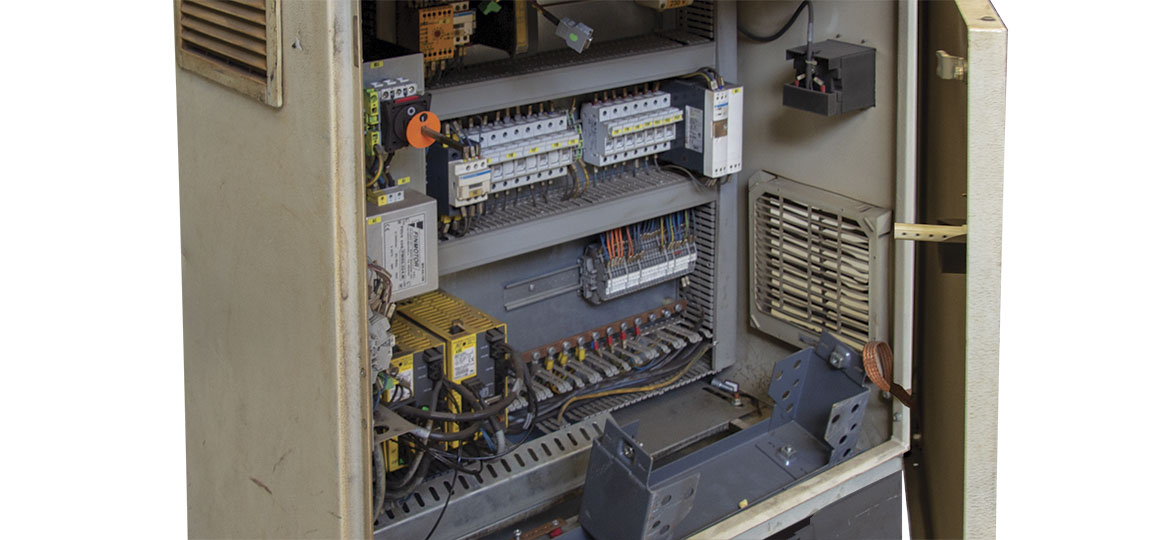

Electrical cabinet

In the complete retrofits is generally provided a new electrical cabinet.

This guarantee the use of new components for the electrotechnical parts and the reset of the problems connected to the reset of the complements.

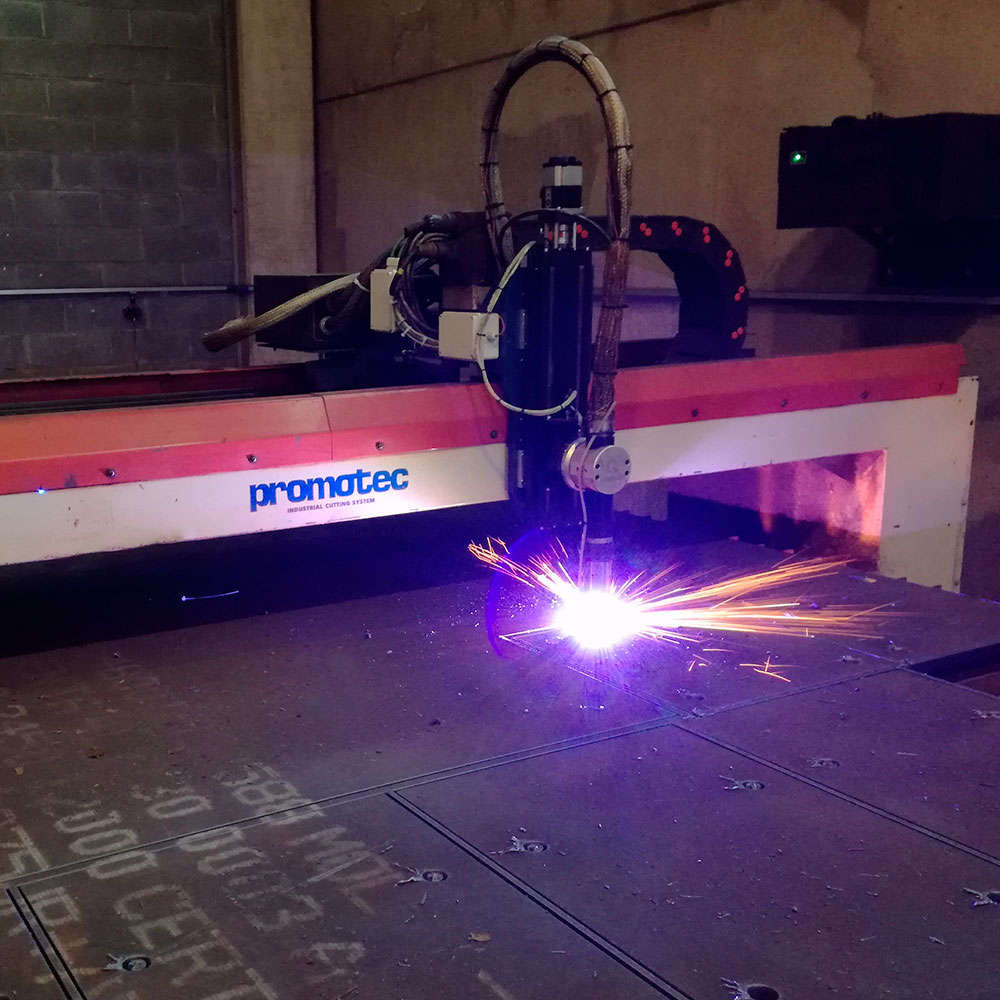

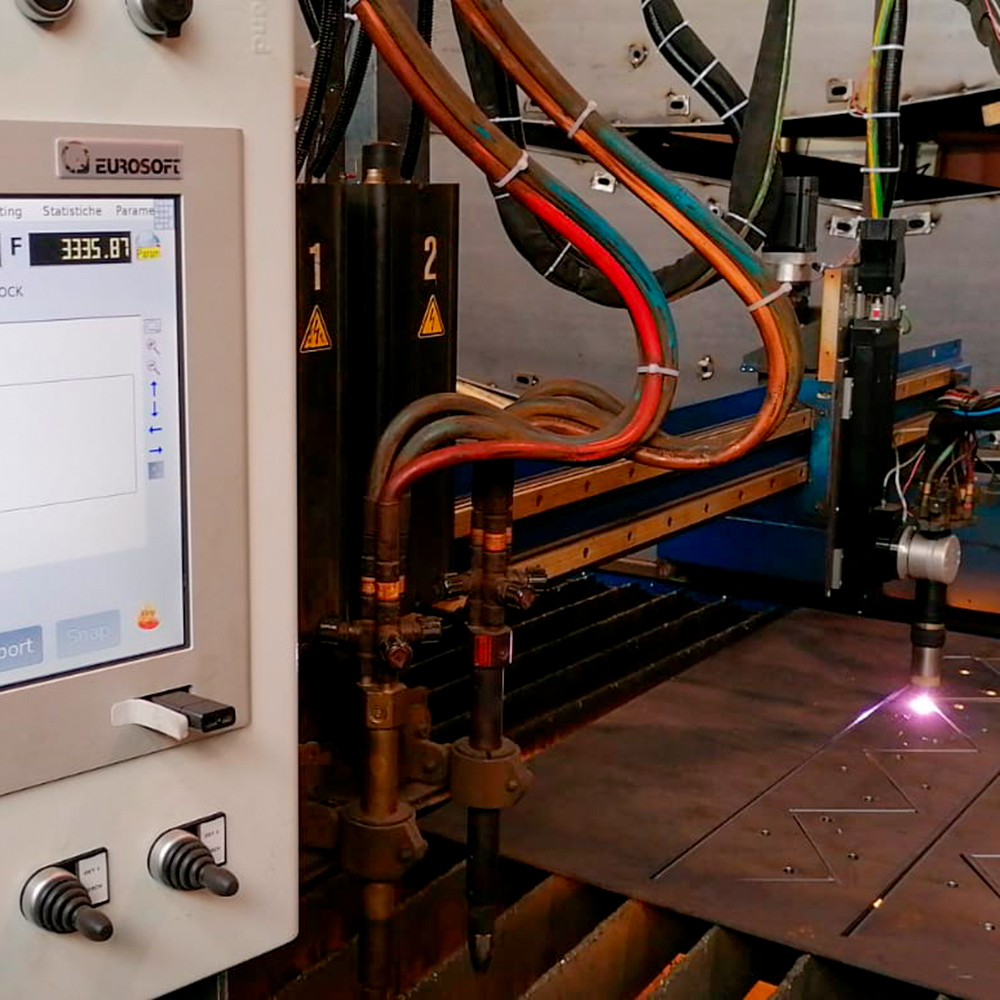

New components

We create a new life to your machine with the add of components (height control, laser pointer, …) and/or the replacement of the cutting sources (oxyfuel, plasma, waterjet …)

INDUSTRY 4.0

The numerical control is prepared to comply to the requirements Industry 4.0. We have a specific software and of technical advice to assist you to the certification process.

Mechanical overhaul

We make a check on all the mechanical structure of the machine regenerating or replacing the defective parts.

Recertification assistance

We provide the necessary documentation and support for the retraining of the machine.