Revolution 4.0 is adaptable simple intuitive

To produce does not only mean to bring your items on the market. In fact, it’s important to estimate the time necessary to create them too. The future of a company depends on the ability to focus on the details of every productive phase analysing its timing, procedure, costs and result. Often, due to complicated organizational char and too long periods to get all these informations, approximative and far from the truth costs are developed. Revolution 4.0 it’s an intelligent software procedure that allows to make the cad/cam CutExpert and the numeric control ECP1000 interact finding every information useful to Industry 4.0 certification.

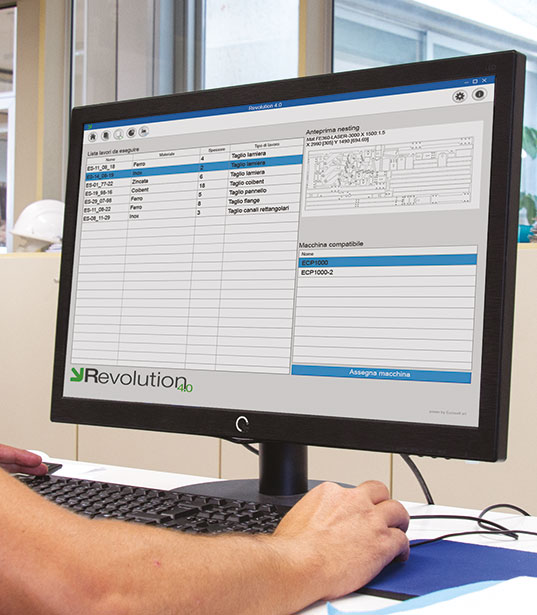

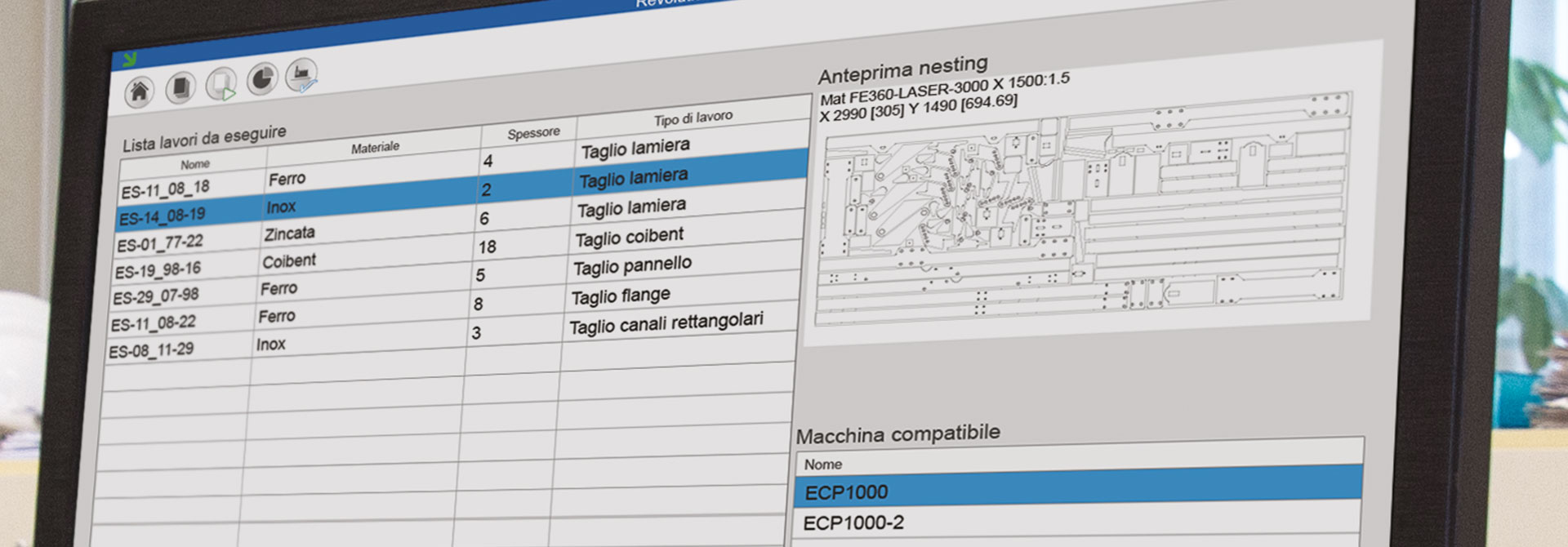

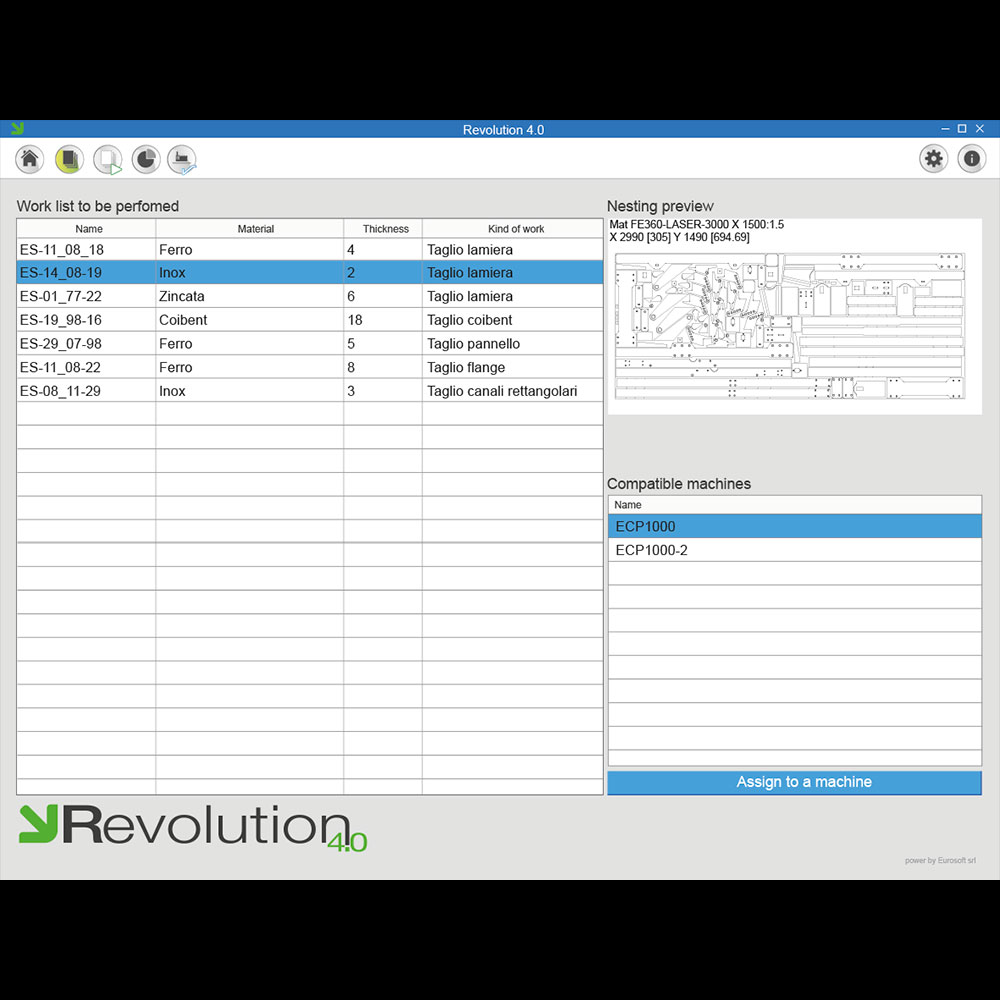

Really intuitive MENU

Machines management

It manages and controls multiple machines on the same internet line with a single module

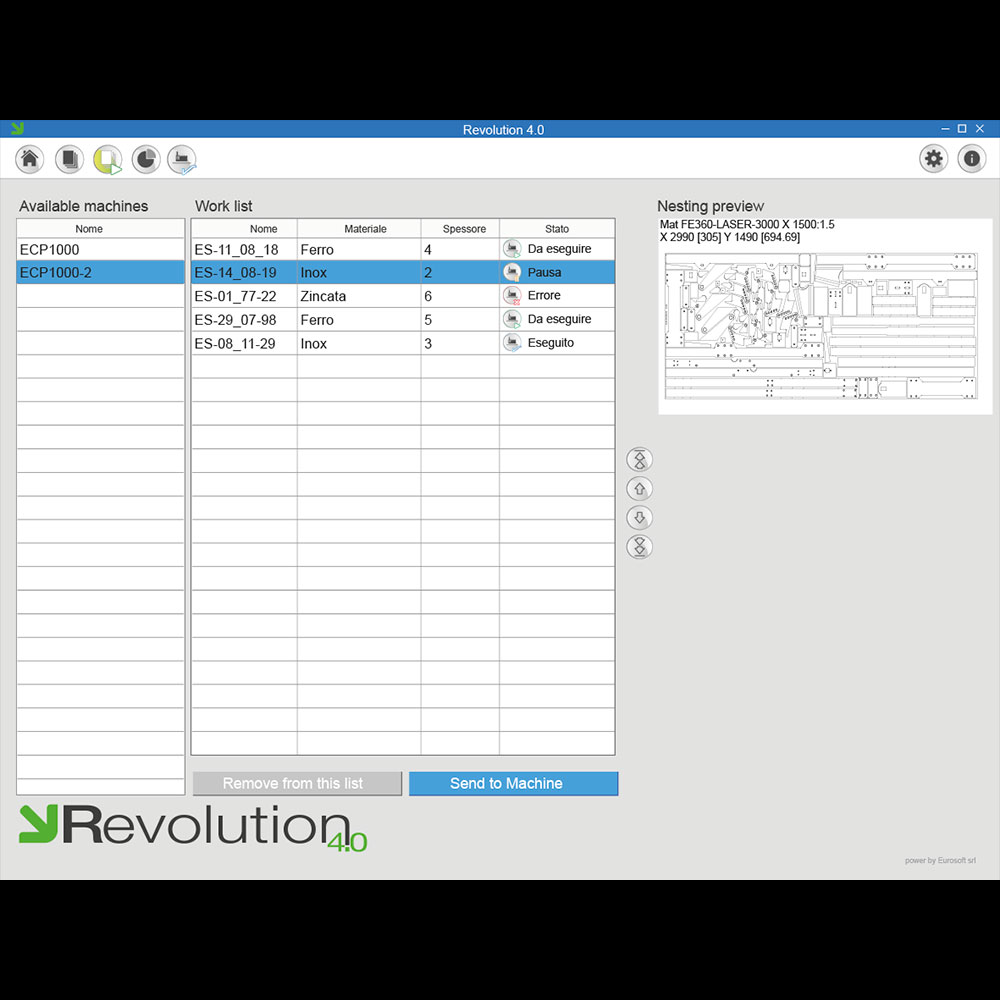

Assign jobs

It allows you to assign the jobs created with CutExpert to the machine chosen from the list in order to plan and optimize the working hours of each one.

Orderable work list

It allows you to order the order of work to be performed and send to the numerical control. With the option of real-time displays, by connecting to the CNC, it is possible to control the processing in progress, the finished one, the interrupted one and the one awaiting execution

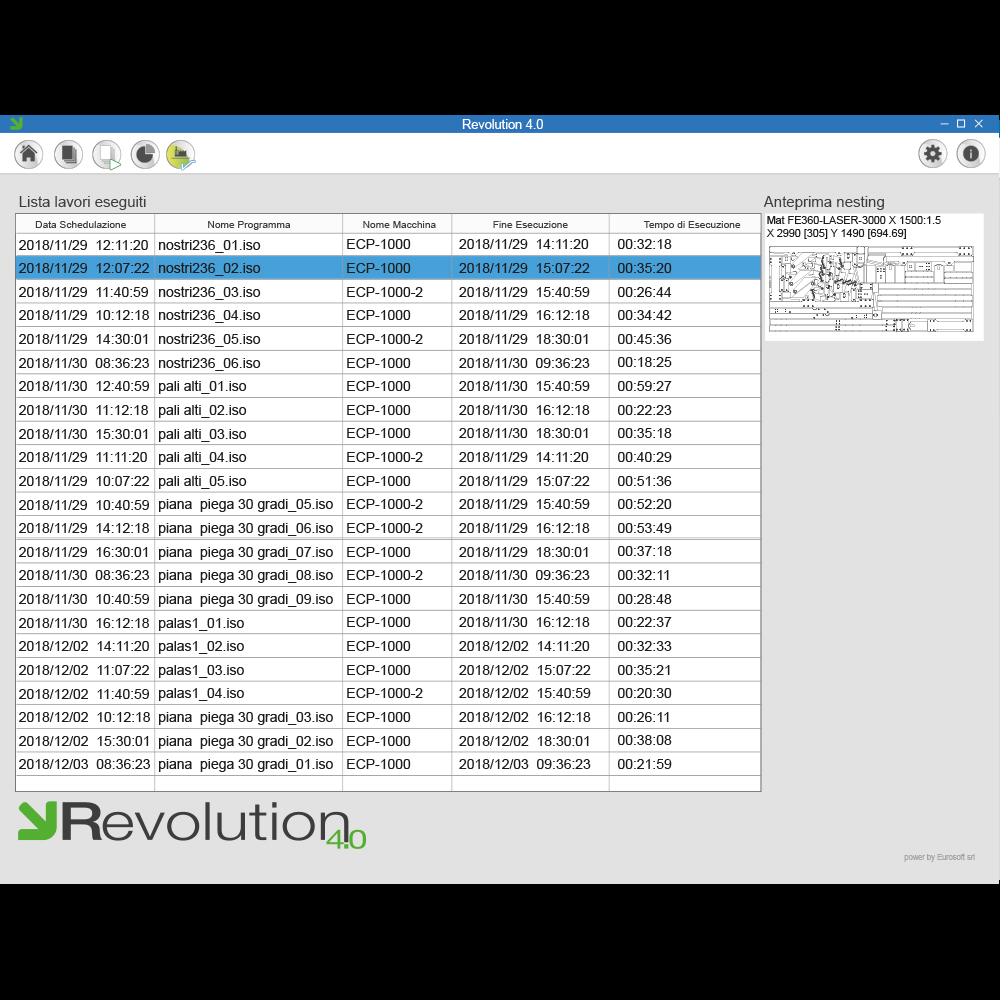

Job history

At any time we can consult all the works carried out

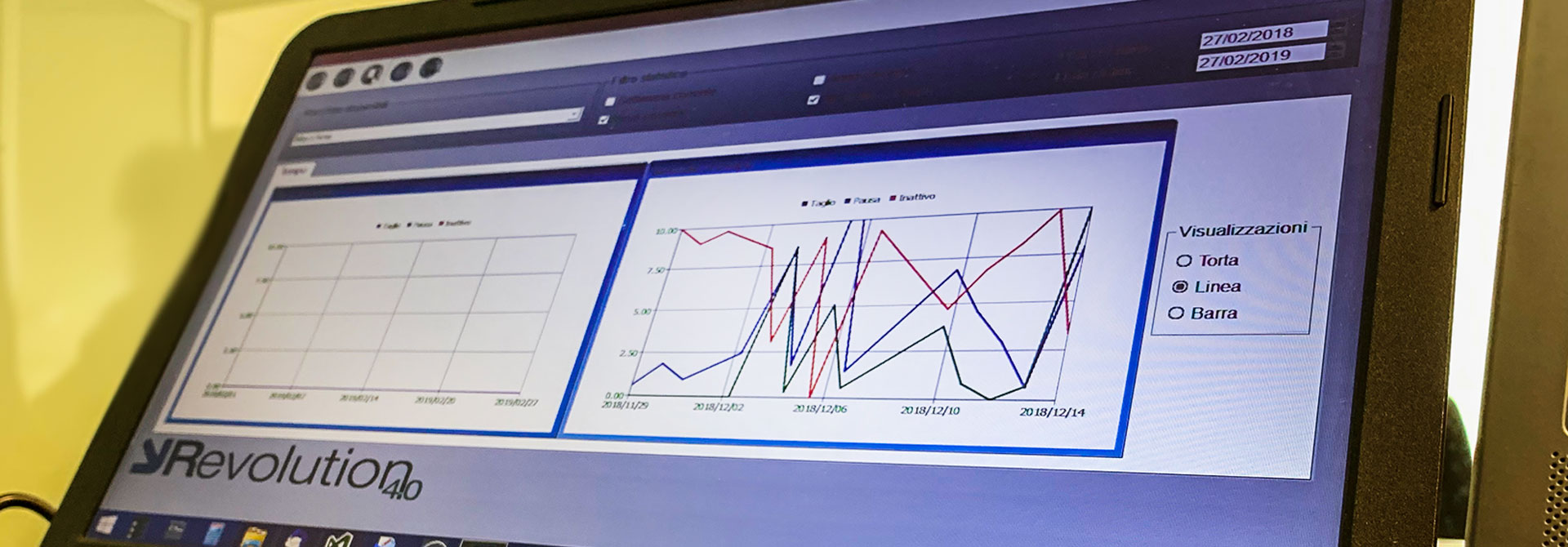

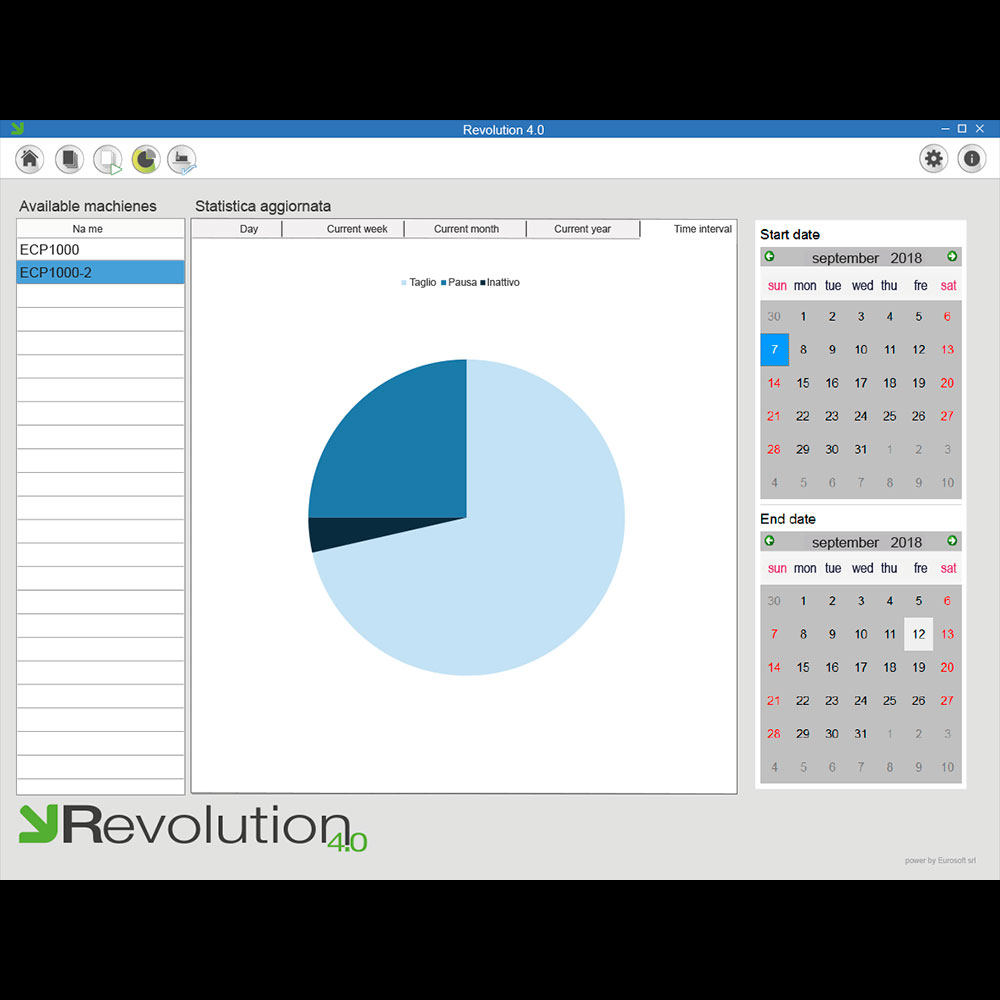

Analytics

Keep track of individual work times. For each machine connected to Revolution 4.0 we can check the actual cutting, pause, error and inactivity times. The display has 4 interface options and dynamic search (day, week, month, year and customizable time interval)

final balance

Thanks to the perfect integration, the CutExpert cad / cam software designed by Eurosoft allows you to receive back the data relating to the cutting times and to have a final balance regarding each sheet of sheet metal processed by automatically updating the work estimate. The "real" data obtained can be used to develop precise future estimates aimed at total customer and operator satisfaction.